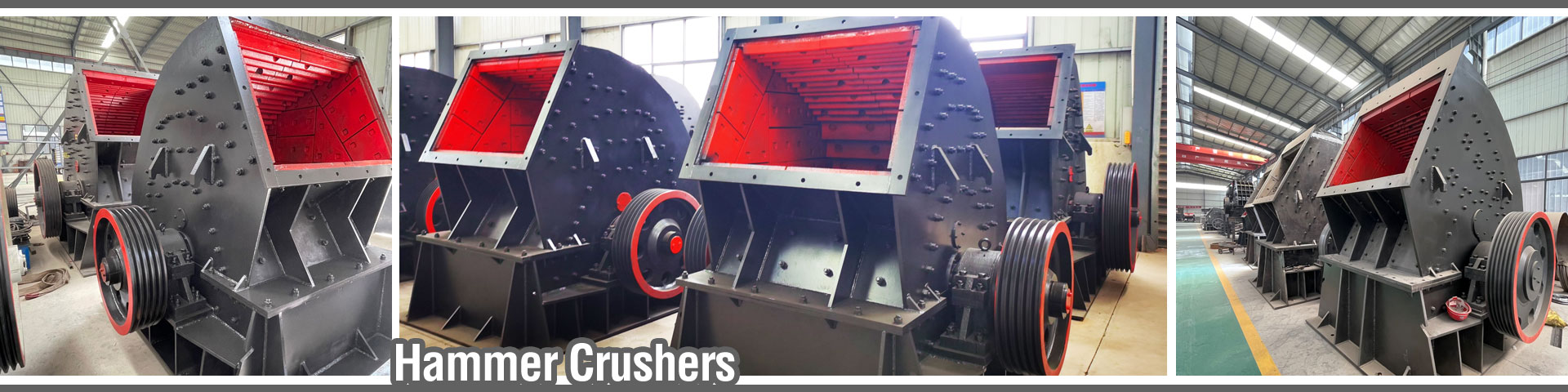

What is Hammer Crusher

From the name of “Hammer crusher” we know that this kind of crusher mainly work with the hammers. Follow the single and high-efficiency structure, whatever the wet or dry materials, they all can be striked by hammers. Particularly this kind of crusher is widely used in metallurgy, mining, cement, coal, construction materials and expressway, chemical industry, etc. Especially for medium hardness and fragible materials like limestone, this hammer crusher could get perfect powder crushing effect. Matched different demends, the discharge port could be also adjusted.

Hammer Crusher Features

* Double belt pulley, reducing motor cost

* Hign manganese alloy impact plate, improving crushing ratio of stone hitting iron and capacity;

* 0.5kw power consumption for one ton output

* Adjustable bottom screening plate, wearing parts fully-covered structure, aggregate shape is polygon, the product is round and rule ,compressive strength is high

* 270 degree screening plate and hammerhead dislocation arrangement scattered, reducing powder capacity

Hammer Crusher Working Principle

Hammer crusher mainly relies on the impact force to complete the crushing. When the hammer crusher works, the motor drives the rotor in high-speed rotation. The materials are sent into the crusher chamber evenly and after a high-speed impact of hammer, the material is crushed into a smaller size.

At the same time, the material’s own gravity makes material dropped to the panel and sieve from the high-speed rotating hammerhead.

The material larger than the sieve mesh is remained in the screening plate for further impacting and grinding. The material smaller than the sieve mesh is discharged from the hammer crushing machine to the material piles.

* The structure will be different as customers’ requests.

Specifications

| Models | Specification | Feed opening | Rotate speed | Capacity | Power |

|---|---|---|---|---|---|

| mm | mm | rpm | TPH | KW | |

| SH1310 | 1000-1300 | 600 | 500 | 150-200 | 160 |

| SH1416 | 1000-1600 | 600 | 500 | 200-280 | 200 |

| SH1616 | 1200-1600 | 700 | 420 | 280-400 | 200 |

| SH1620 | 1200-2000 | 700 | 420 | 380-530 | 250 |

| SH1820 | 1600-2000 | 700 | 350 | 500-700 | 355 |

| SH2022 | 2000-2200 | 1000 | 350 | 600-860 | 500 |

| SH2024 | 2000-2400 | 1000 | 350 | 1000-1400 | 630 |

Options

| Options |

| Maintenance Platform |

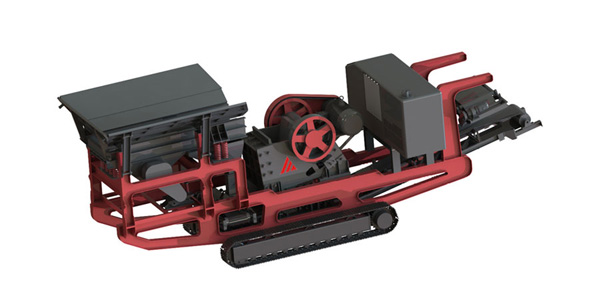

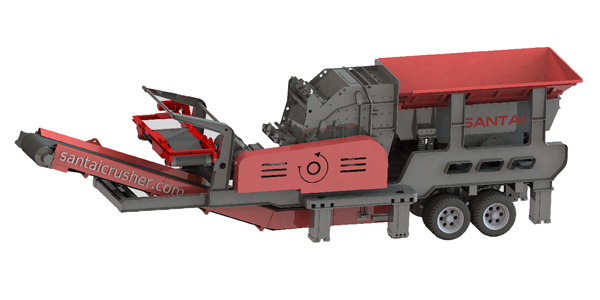

| Mobile or portable structure |

| Diesel generator power |

| Structure customization |

| Control room |