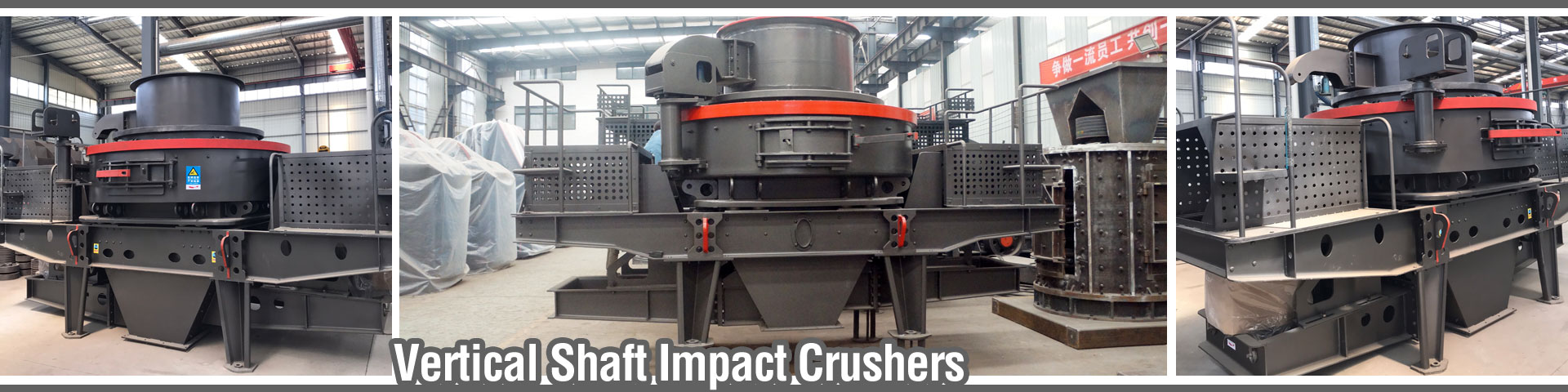

What is Vertical Shaft Impact Crusher

Vertical shaft impact crusher is widely used in crushing and reshaping of rock and artificial sand making. It is suitable for crushing of fragile materials like pebble, calcite, granite, quartz, concrete, dolomite, bluestone, iron ore, limestone that below level 9 of Moh’s hardness rather than viscous materials or stone materials containing much solid.

Vertical Shaft Impact Crusher Features

* High-performance production efficiency, low power consumption

* Integrate the function of sand making and granule shape optimizing

* Good grain shape, reasonable sand grading

* Unique design, easy maintenance

Vertical Shaft Impact Crusher Working Principle

The raw materials are fed into the vertical shaft impact crusher by the vibrating feeder. The materials are divided into two parts. One part falls into the high-speed centrifugal plate from the feeding pipe at the center of distribution disc. This part of materials is given high rotating speed and flung out through the runner of centrifugal plate. Firstly, the flying materials collide with the other part of materials which fall down from the rim of distribution disc, and then all the materials impact the lining of crushing cavity. As mentioned above, the materials will be impacted, rubbed and grinded repeatedly until fall out of the crushing cavity and into the discharge hopper.

* The structure will be different as customers’ requests.

Specifications

| Models | Feed at centre and side | Feed at centre | Feed size both | Feed size centre | Power | Rotate speed |

|---|---|---|---|---|---|---|

| TPH | TPH | mm | mm | KW | RPM | |

| SV7611 | 120-180 | 60-90 | 35 | 30 | 110 | 1700-1890 |

| SV8518 | 200-260 | 100-130 | 40 | 35 | 180 | 1520-1690 |

| SV9526 | 300-380 | 150-190 | 45 | 40 | 264 | 1360-1510 |

| SV1140 | 450-520 | 220-260 | 50 | 45 | 400 | 1180-1310 |

Options

| Options |

| Maintenance Platform |

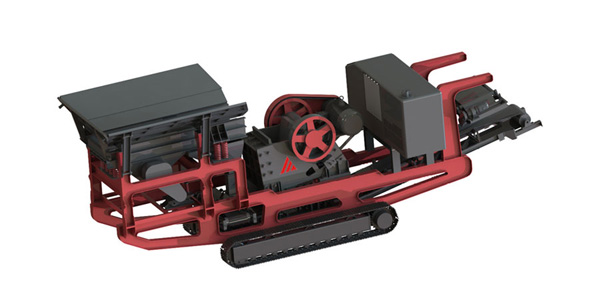

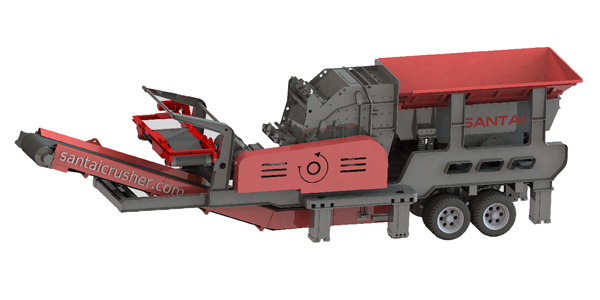

| Mobile or portable structure |

| Diesel generator power |

| Structure customization |

| Control room |